Make Work Easier with One of Technology’s Latest Drill Machines!

Drill machines have come a lengthy way in history because of the importance they add in several areas such as: infrastructure, pulling out and many fields that involve building, demolishing or exploring. There are a variety of types of drills available in the market to enable customers to have infinite options when it comes to choosing the right one. When choosing it requires sufficient information about the drilling machine and how it is capable to meet the require the particular customer would want it to meet. There are various examples of good quality drills that have been experienced and are certified to be user welcoming and extraordinary. They consist of: pillar drill machine and a V- belt driven radial drilling machine.

These are able to carry out drilling systematically and have surprised many customers because of the way they have been carefully designed to perform professionally. This equipment has systems that contain a routine spindle in a system head that is installed near a flexible radial arm that can be brought up or summary. They are intended to make sure that they offer high quality routines that can be customized above the item while executing the drilling exercise. It can be used for investigation gaps that many machines are yet to attain. Get your hands on this equipment today and watch drilling becomes easier.

Features and application that Pillar Drill Machines have

These delicate tools have an unbending structure that offers firm hold up in the route of the drilling work out which enables it to last over time making it highly durable. Its part is readily accessible and easy to access therefore should any replacement of parts be required one needs not to worry about spending a lot of time looking for extra part for the Drill equipment. It is simple to sustain which helps the customer save on cost while maintain and its precision parts are made of the EN-8 steel.

The pillar drill machine is mostly designed for fast metal removal rate which is highly constructive for extraction of ores as far as mining is worried. The octagonal figure pillar group acts like a rib provided that more rigidity and hold up that keeps it standing. It has a drive to the spindle that goes through a six-splined covering from the within making it firm and hard to get damaged.

Features and applications of V-Belt Driven Radial Drill Machine

This Drilling equipment is prepared with pasts such as a blocked grain cast, iron column, high quality arms, and geared work beginning. Its moving parts are completed to close tolerance while it has a steel spindle, a pinion and a spindle ram which enables the operator to easily use and continue it. It has extraordinarily precise drilling performance of high feature that enable the operator to execute radial drilling in a fast and efficient manner that will save time and energy which in turn increases work efficiency. This device has managed to incorporate complicated in its designs with a touch of simplicity.

Drilling can now be an enjoyable exercise thanks to these highly modern machines that have fully embraced equipment to help the mechanical industry keep up with the efficient society.

All about a Drilling Machine

Machines build our work simple, reduce the attempt and raise the efficiency. It used for holes in a work-piece are known as drilling equipment. It is the process of produce a round hole with a turning cutter, called drill, in any material. Also known as drill press, drilling device is used for holes of a diversity of sizes and accurate depth in any outside. These have finished all kinds of composite jobs very simple.

It is used for industrial, commercial as well as family purposes. It is an important tool used for drilling in metal dealing out industry, developed industry and for construction work. These are also designed to be used for health check purposes, for whole missions and in industries like manufacturing, metalworking, woodworking and stonework.

Additionally holes, drill tools are also used for farm duties like tapping, spot facing, reaming, counter sinking and counter boring etc. Manual equipment are operated with hand power and automatic drill machines are automatic with electricity. These are also permanent on the floor or are mounted on a stand.

A drill has a head, a radial arm and a gearing machine. These machines have high performance value but low protection cost. Those made from good quality materials have high correctness of the machining work.

A multiplicity of drilling machines for different applications is available. These are:

1) Pillar drill machine – These have rigid structure and vibration free device. These are used in special industries to drill holes in material, rocks, heavy duty equipment, metal sheets, plastic, wood, glass etc. These equipment have durable bits due to which their effectiveness and performance increases.

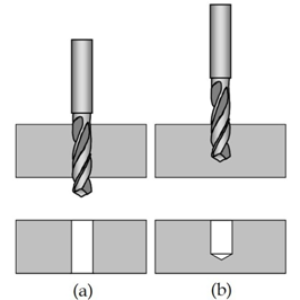

2) Radial drill machine– These are accessible in various magnitudes of drill head, base plate and capacity. In this equipment the head is mounted on a radial arm. In order to adjust the position of the drill above the work piece, the radial arm can be rotated, raised or lowered on a vertical post. It is known for its exactness, correctness and efficiency. In the plain radial drill the spindle is straight up and does not swing.

3) Drilling cum milling machine- This is two-in-one process appliance which works for drilling as well as milling operations.

A flexible drill machine contains a box with different types of drill bits and it can make holes of necessary sizes. All geared mechanism comes in various capacities for holes of a variety of radius. Pneumatic machines are powered by compressed air.

The machines that are used for manufacturing and profitable purposes, are mechanical by electricity, and are particularly designed for an extensive duration use. Drill machines used in the steel manufacturing are heavy duty equipment with high functionality and strength.

Low capacity tools are used for family purposes like plumbing, nailing, fitting bathroom fixtures etc. While using these equipment at home one must follow the safety procedures, and use safety gears, like glasses, gloves and jumpsuits.

So, get good quality care of your equipment, it will last longer and serve up you better. Oil it occasionally to put off rusting and clean it correctly after every use. Purchase a unit according to the natural world of the job you want to carry out.

Drill FAQ – What Is Drill, Types of Drills, Drill Bits, Safety Measures of Drill Machine

Drill FAQ

Drill FAQ will give you thought about the types of drill equipment and their various industrial applications. Here it is tried to explain the common queries and needful information for drilling mechanism. For additional inquiry about the tools and their technological requirement, you can visit the website – www.parmardrill.com or www.parmardrillmachine.com

What is drill?

Drill is a tool used with cutter device like drill bit to drill a variety of size of holes in solid equipment like metal, wood and concrete etc.

What are the available types of drills?

There are various types of drills such as manual hand operated drills similar to bow drill, gimlet, breast drill and push drill. Electrical drills are pistol grip drill, hammer drill, cordless drill, drill press, radial drill and drilling cum milling mechanism.

What are drill bits?

Drill bits are the cutting tools used to generate cylindrical holes in solid resources. Drill bits are held in the drills to get torque on insurgency which creates holes.

What are the types of available drill bits?

There are a variety of types of drill bits used in Industrial applications. Universal drill bits are used to create holes in wood, metal, plastic and others. There are dissimilar variants of worldwide bits like twist drill bits, step drill bit, unibit, hole saw etc, Metal drill bits as the name suggest, is used in metalworking for drilling.

Variants of metal drill bits are middle and spotting drill bits, core drill bit, countersink bit, ejector drill bit, gun drill bit, index able drill bit etc. Wood drill bits are used for drilling in wood with dissimilar types of bits includes lip and spur drill bits, wood spade bits, spoon bits, forstner drill bits, center bits, auger bits, gimlet bits and adaptable wood bits etc. There are other bits used for dissimilar resources like diamond core bits, masonry drill bits, glass drill bits, PCB drill bits etc.

Where Pillar drill machines are used?

These are used to drill the solid resources with different sizing capacities ranging from 13mm to 40mm. It is used for tapping, screwing, counter boring, lapping etc. Easy setting up and flat operation with this type of drill press have made it more popular in profitable usage.

Where Radial drill machines are used?

Radial arm to drilling increase the action adaptability. Drilling of large and heavy metals and solid materials are executed quite scientifically with correctness and precision. The high quality steel parts, drilling column, arms and geared work head increase the patience capacity of the machine. These heavy capacity radial drills are used where it needs to bear high drilling challenging for drilling heavy metals with accuracy work ranging from 25mm to 40mm.

Why to use all Geared radial drill machine?

This is the superior radial drill equipment and used in the industries where required high presentation and precision drilling. It equipped with gears can greatly handle and adjust the speed of spindle to improve the drilling correctness with high drilling force. It is used with automobile feed and fine feed to drill 40mm, 45mm drilling capacities in metalworking industries.

Where to use Drilling cum milling machine?

This two in one combo task machine is used for drilling as well milling and other machining like slotting and tapping. This high performance multi tasking drill machine is used where several job work needs to be done by a single operator infrequently or frequently.

What are the security procedures one must take during drilling operation?

It is one of the risky instruments during drilling implementation. Several precautionary procedures can put off the accidents like always use holding device to fix the work portion from being escaped. Don’t tremble/regulate the work piece while drilling is on. Use brush to clean the drilled material to avoid burn. Stay any of the flammable objects away from the drilling place.

Hold the drill machine in a straight line during drill cutting. Keep the drilling table clean during and after the procedure. One must use face guardian to protect face and eye during drilling. Drilling must be careful to avoid fracture of drill bits that can harmful to the operator. Check the drill bits and drill unit well before process. Drill bits must be sharpened.

The Top Mandatory Aspects of Drilling In Industries

Common Forms of Piercing

Stabbing has different connotations when it comes to industrial procedure. It is functional in a variety of ranges depending on the strength required. In addition, this application is implementing over dissimilar materials and surfaces in agreement with the industry. Some of them are oil well drilling, piecing on work materials, creating holes on metal surfaces, grinding smaller to larger sized components, etc.

Metal Industries and Piercing Requisites

The toughest and most demanding part of stabbing is the one that is done on metal exterior. If the work material is heavier, it would be more demanding without the help of equipments. Metal industries require this procedure for making holes, for combining two or more mechanism at a single point, shaping tools to its precise from, sharpening materials by deforming surfaces, etc.

Industries which prefer Tooling Operation

This function can be seen in automobile, mechanism manufacturing and many industries which make use of different types of metals, wood and plastic as raw material.

How wood works are intensified with Drill?

Unexciting equipment is featured with a tool bit or sharpening stipulation, that sharpens the specific area in terms of creating dimensional holes or cavity. The cavities have to be created based on the corresponding dimension to be combined with other parts to form a final product like in making of furniture’s. In the same way, when it comes to wood work, boring means a lot, it remains the connective point for creating the preferred object.

Countersinking

Countersinking is a kind of procedure that helps to make cone shaped outside on the mouth of an already existing hole. It is done to link the material with flat beginning screw or rivet. It is useful with the help of instrument bit that can be friendly to the equipment. Moreover, this kind of sharp is also preferred for eliminating inflections or sharp edges present in the hole and radial drilling machine can be applied to obtain these situation.

Creation of Holes

Holes are created for fixing fundamentals and for inserting more components that stay in similar dimension with that of hole. Precise of dimension is more important and this can be obtained only with the help of special equipment like pierce machine. For creating precise holes on heavy duty work equipment v-belt driven radial drill will stay the ideal choice.

Grinding –Masonry Works

Grinding is yet another form of compulsory requirement in masonry wood works. It helps in removing the burrs and keeps the exterior smooth. Radial device with v-belt drive works efficient for this function also.

Drilling Large Work Pieces

Radial drilling equipment is one of the top choices of machines that can be used for stabbing large or heavy load work materials. This machine is available in new features such as the v-belt drive is yet another beneficial feature that helps in this regard.

Conclusion

Drilling is favorite in different industries as it is establish to be compulsory to combine work materials. There are particular forms of equipment that can be applied to reach precise tooling at reduced wastage.

How Drilling Functions Are Manifested for Accuracy In Wood Work And Furniture Making?

Why Boring Requisites Need Accuracy?

Boring or drilling functions are of a variety of sorts and the proportions vary in different industrial sectors. Stabbing is done for different fundamentals such as for fixing two work pieces or preparing the work material for core purpose. Drilling equipment is the right option for accurate boring and the same process is establish in several industrial such as metal, heavy metal and wood, heavy duty materials, plastic, etc. As far as in wood is concerned, either the process is applied in heavy furniture manufacture where model such as a radial drilling device will be suitable to handle large and heavy wood work pieces which cannot be pierced easily with a basic module. In addition, earlier days the demand for manual support seemed higher in order to bore, with the advent of spindle module and rotatable radial arm features machines are relied for easier wood stabbing works.

The List of Interesting stabbing Applications in Different Industries

- V-Belt Driven drilling –It is mainly applied to pierce the work materials for creating holes and can be used on a range of materials. V belt driven equipment comes with different condition which varies in the boring capability, spindle nose and column distance.

- A radial drilling machine is also an eventual choice for different works. In addition, it is a flexible device which can be chosen based on different dimensions and capacities.

- An all geared drill tools is a totally automatic device where it is no more required to change the dimension of stabbing of the work piece if more piercing or tapping or screwing is required on the work material.

- For weighty duty operations, a radial drill or all geared radial will stay the best options.

- A pillar drill tool is a ideal device for wood works and for shaping or sanding also.

How to Obtain Perfect Accuracy with All Geared Drilling Machines?

These mechanisms are available with unbelievable technologies and condition. There are no more requirements for man power assistance like in earlier days. With more than a few automated functionalities equipped with latest drilling machine models, the ease of this and related tapping, screwing purposes can be obtained with a single device. Moreover, before ordering for a stabbing device it would be better to consider the below suggestion for correctness, accuracy and durability. Some of the important suggestions are,

- A radial drill device can be chosen to obtain precision of boring in heavy duty metals. In addition, it is an automated device where man power requirement is very less.

- In addition, imported radial drill equipment from a professional country like India will take you to knowledge frequent benefits like smart working, sturdiness, quality, reasonable pricing, etc

Conclusion

Finding a genuine producer of drilling equipment or a drill device supplier is not tough thing to carry on with provided the depositor need to be updated about the types of dreary equipments obtainable and the possibilities in tradition made designs as well. This will build the search easier. Additionally, with the help of online search one can find the list of manufacturers and the equipment obtainable by them. Thus, contact a reliable tools designer and make public the industrial fundamentals to obtain perfect equipment.